Cheese racks

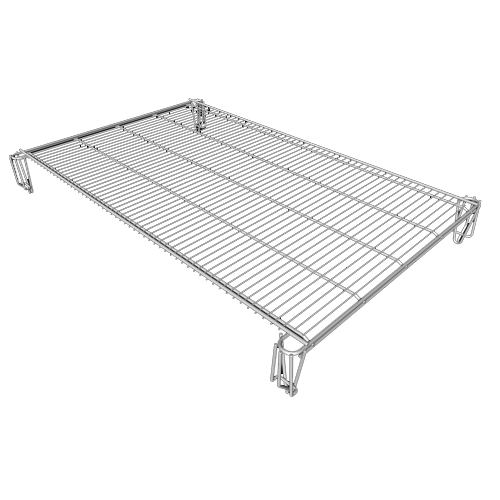

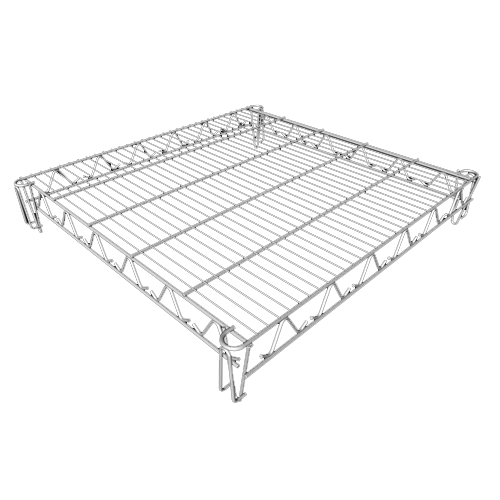

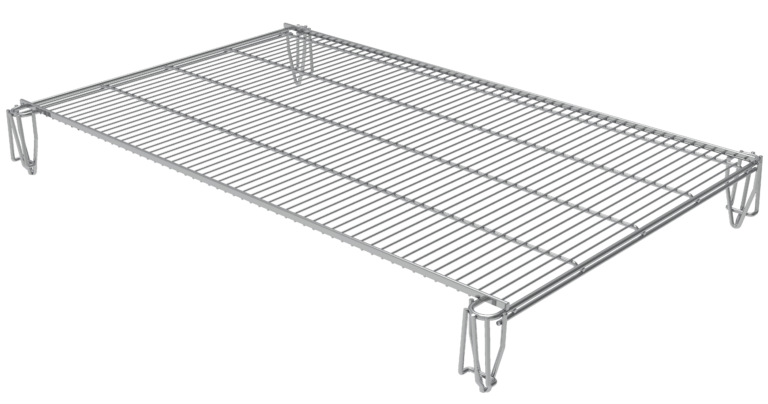

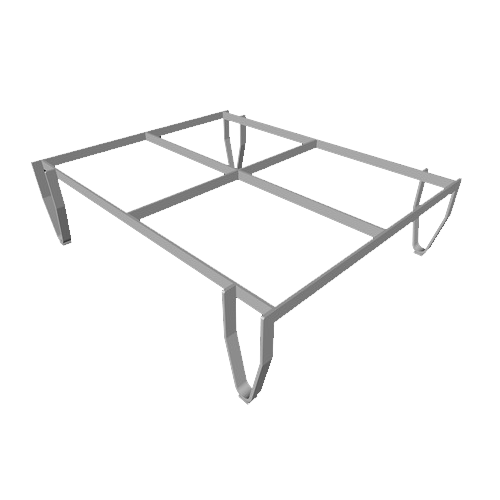

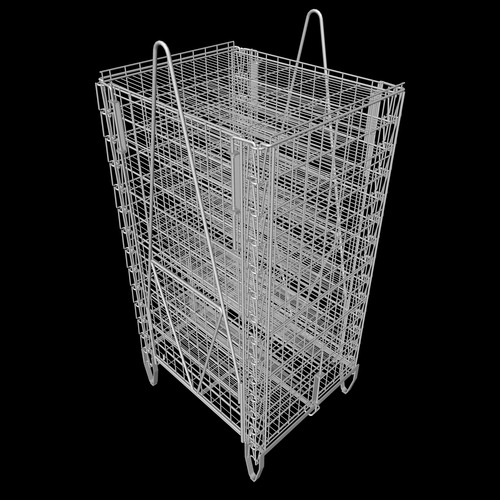

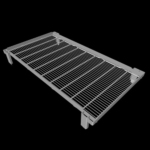

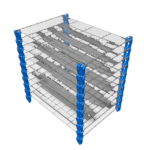

Single ripening racks

Simple ripening racks are designed to provide a high-performance, cost-effective solution for the cheese ripening process. Their high rigidity ensures that cheeses are held securely, while guaranteeing optimum ventilation. Perfect precision in the height of the stacks of trays ensures more even ripening and consistent quality. What’s more, the interlocking legs are designed for easy assembly and maximum stability during use.

Our racks are available in a variety of sizes to suit your specific needs, so you can choose the ideal size for your production. The useful height of the trays varies from 40 to 300 mm, offering the flexibility needed to meet the requirements of every cheese factory. A simple, efficient solution perfectly suited to cheese ripening.

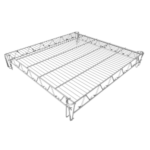

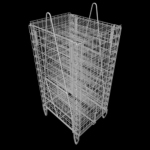

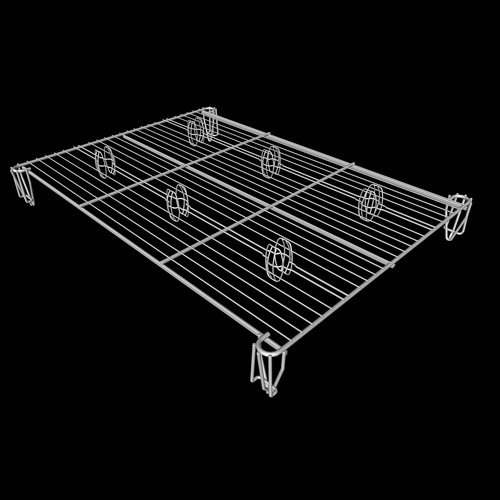

Brining racks

Brining racks are essential equipment for cheese salting, ensuring uniform immersion in the brine. They ensure even salting, while facilitating cheese handling during this crucial ripening stage. By guaranteeing optimum circulation of brine, they contribute to quality ripening, in compliance with hygiene and safety criteria.

Our brining racks are made of stainless steel, a robust, corrosion-resistant material that is easy to maintain. They are designed to withstand heavy loads, while allowing optimum circulation of brine around the cheeses. Available in a range of sizes, they adapt to all types of cheese, offering flexibility and practicality.

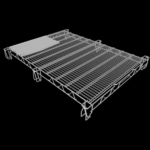

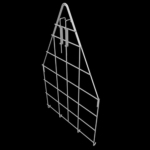

Moulding and acidification racks

Moulding and acidification trays are designed to be highly rigid, so they can easily support the weight of the curd during moulding. Their perfect flatness and precise shape prevent any curd leakage, guaranteeing clean, flawless production.

Thanks to the texture of their support, they ensure optimum curd support, facilitating the manufacturing process and enabling better molding management.

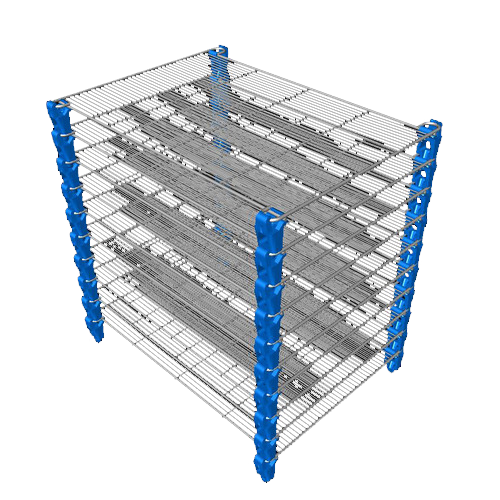

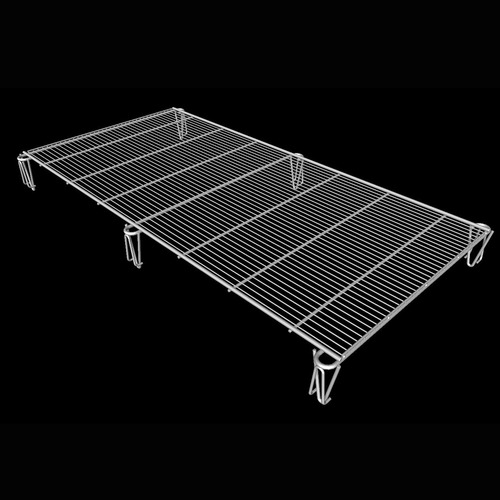

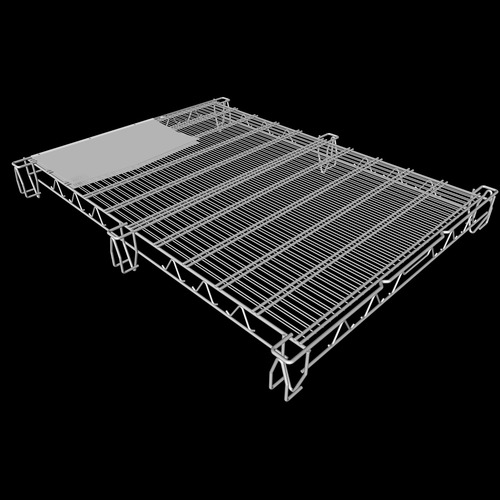

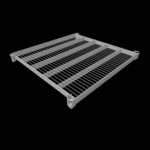

Automatic Line Screens

Automatic line racks are designed to meet the performance and efficiency requirements of modern production lines. Their high level of dimensional accuracy prevents any blockages or malfunctions as the trays pass through the automatic lines, ensuring a smooth, continuous production flow. Panels are reinforced with sandwich frames, galleries or profiles, guaranteeing optimum rigidity for greater durability and strength.

For more precise and stable stacking, our racks are equipped with more rigid legs, available in several materials: calibrated wire legs, sheet metal legs, plastic legs or profiled legs. This flexibility in the choice of legs means that the trays can be adapted to the specific needs of each production line, while ensuring perfect stability and precise alignment to maximize the efficiency of your automated processes.

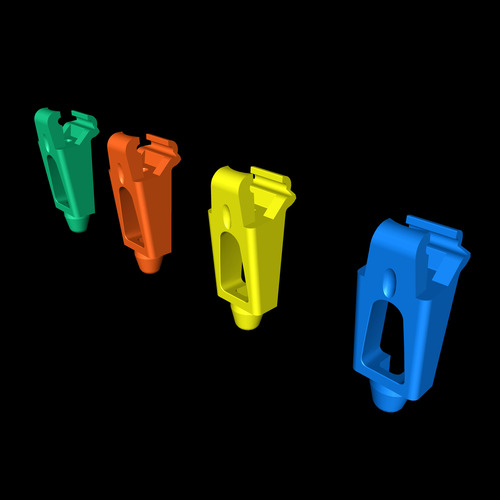

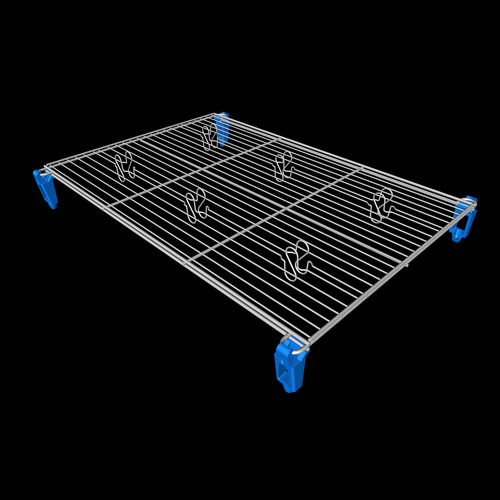

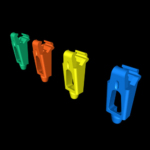

Cheese racks with plastic feet

Cheese racks with plastic feet are designed for optimum precision in cheese stacking, ensuring perfect stability during the manufacturing process. Precise height adjustment of legs and stacks ensures uniform, stable stacking. The plastic legs are available in different heights, from 50 to 120 mm, and are designed to allow water droplets to drain away, thus preventing stagnation and optimizing ripening. In addition, several colors are available to facilitate visual identification of batch references.

Easy to adapt, these plastic tabs enable simple height changes on your trays, as well as rapid replacement of damaged tabs. Our patented variants offer innovative features, such as stainless steel-filled plastic tabs that can be detected by magnetic sensors for precise control, or tabs fitted with electronic chips that can be “read” remotely, guaranteeing complete traceability of your cheeses, from production to maturing.

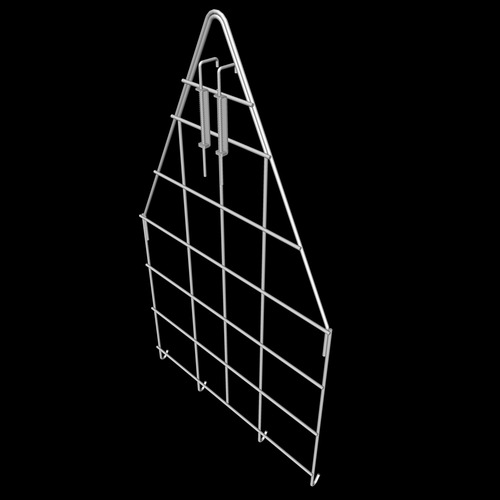

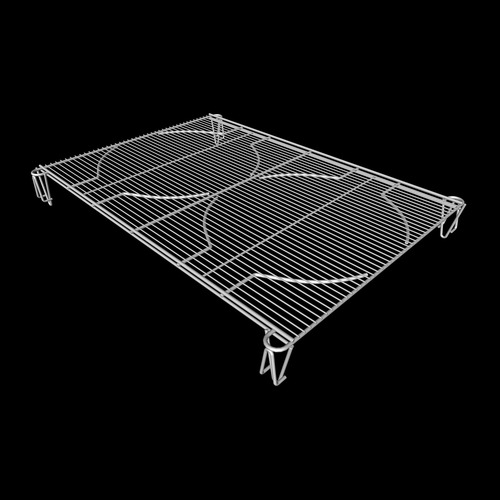

Formed cheese racks

Formed cheese trays are specially designed to ensure precise, efficient turning of cheese stacks during ripening. Thanks to the same precision and rigidity as the “Automatic Line Racks” solutions, they guarantee perfect guidance of the cheese, whether from the inside or outside, and effective blocking of the cheese in the height for homogeneous ripening. This system maintains a stable, regular shape throughout the process.

Our form trays, including log and ball trays, are ideal for holding cheese in the desired shape, while providing optimum support during ripening. We can also produce prototypes to validate the desired shape of your cheese, offering you a solution perfectly adapted to your production needs.

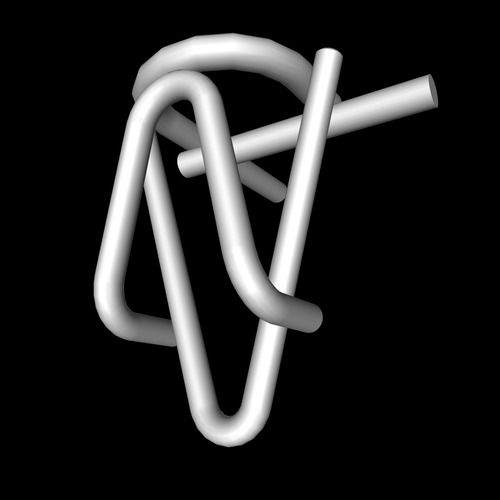

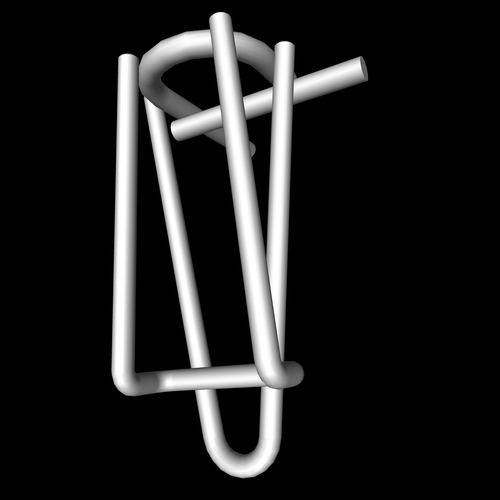

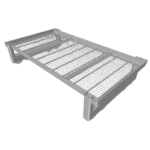

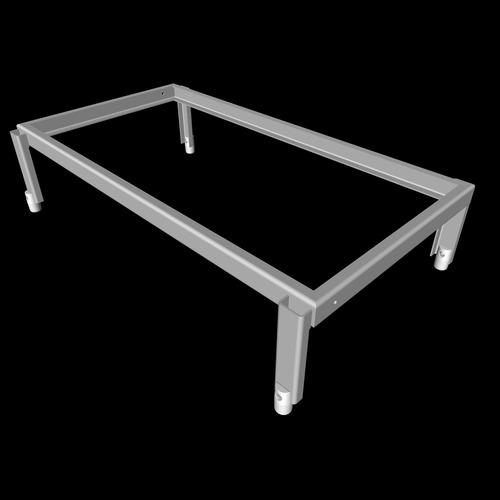

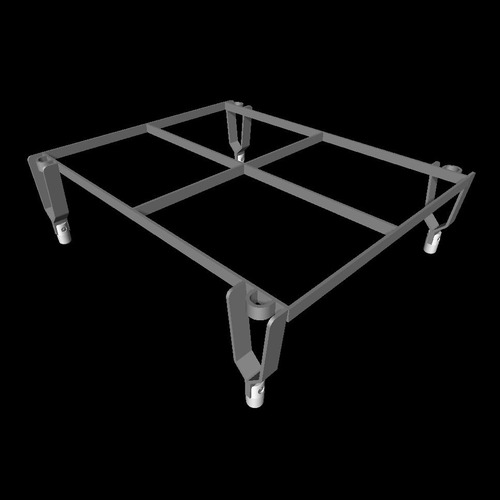

Base/rolling base stands

Cheese-making base stands are designed to offer exceptional strength and resistance, even in the most demanding production environments. Available made-to-measure, our base stands are manufactured with flat-iron or U, H or L-section frames, and bent-plate legs to guarantee high stability. Wear pads and casters in “special food nylon” or polyamide ensure smooth mobility and increased resistance to wear, making it easier to move and manage equipment.

We also offer innovative variants, such as wire base feet, which provide a lightweight, practical alternative. What’s more, it’s possible to include a remotely “readable” microchip on your base feet, to guarantee complete traceability of your products, from start to finish of production. This feature enables precise tracking and optimized product management within the cheese dairy.

High-quality manufacturing

Cheese racks manufactured by TSA-Industries are distinguished by their sturdiness and meticulous design, ideal for ripening cheese. Thanks to our unique know-how, we use top-quality materials that guarantee optimal ventilation and compliance with sanitary standards, essential for successful ripening.

Our racks are designed to maximize hygiene and durability while facilitating the ripening process, ensuring consistent quality of the final product.

Racks designed to last

For optimum maintenance, we recommend cleaning the trays after each use with hot water and a mild detergent, then air-drying them thoroughly. Avoid abrasive products that could damage the material.

In the event of prolonged storage, we recommend keeping them in a dry, well-ventilated place, away from excessive humidity. This will preserve their efficiency and extend their service life.